Life is impossible without energy. Since the production of most goods and services relies on energy, energy goods are a necessary element for all economic activities. Therefore, Behyaar Co has commenced its operations in this field. The active research areas in this company include the design and manufacture of lithium-ion batteries, fuel cells, solar cells, boiler flue gas purification, and helium gas extraction from natural gas.

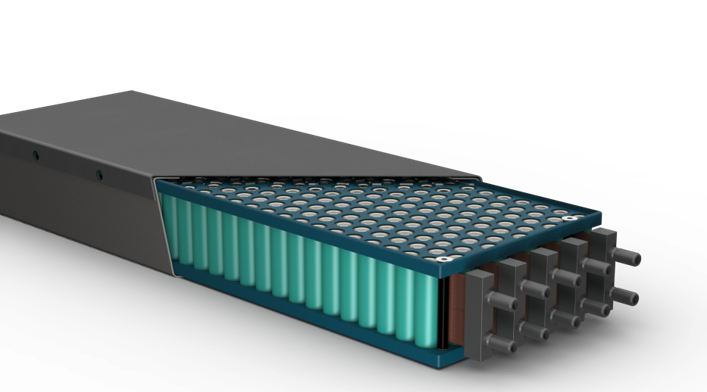

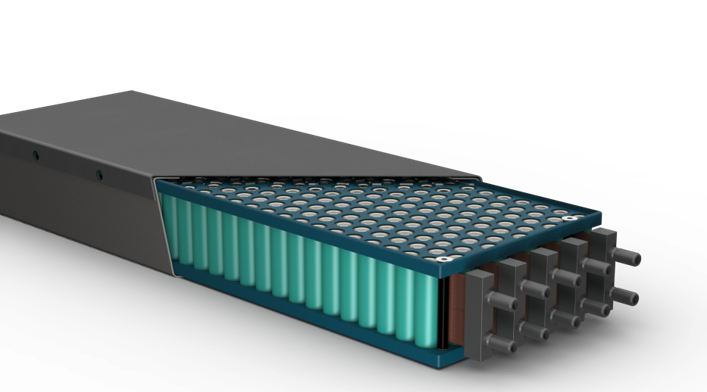

A lithium-ion battery is a type of rechargeable battery where lithium ions move from the negative electrode to the positive electrode during discharge, and from the positive electrode to the negative electrode during charging. Lithium-ion batteries are widely used in portable electronics and electric vehicles, and their application in aerospace and military contexts is increasing.

Why Fuel cell

Energy is indispensable for all processes worldwide. We require on energy for heating, cooling, transportation, industries, and various aspects of daily life. Throughout human history and particularly in modern society, Energy has been vital. However, one of the most pressing challenges humanity faces is energy production, which has evolved over time. In recent decades, factors such as the depletion of non-renewable energy resources, environmental concerns and the imperative for energy security have heightened. consequently, the necessity of accessing new energy sources has become more pronounced. Renewable energy, clean energy, and alternative energy sources (such as biofuels, etc.) Are among the new energy sources developed to address these needs. Fuel cells are a significant technology for power generation, offering high efficiency while producing minimal pollution. They can operate using various fuels, including hydrogen, natural gas, and biogas, with higher efficiency compared to combustion engines. Fuel cells find application in a wide range of uses such as power plants, portable equipment, backup power generation, and transportation. Fuel cells are an important technology for power generation, boasting high efficiency while causing minimal pollution. They can operate using different fuels, including hydrogen, natural gas, and biogas, with greater efficiency than combustion engines. They are utilized in a wide range of applications, such as power plants, portable equipment, backup power generation, and transportation. The fuel cell directly converts the chemical energy to with high efficiency electrical energy and is divided in to different types of membrane used. Among these, the polymer membrane fuel cell, which typically operates at low temperatures, has found widespread applications in various fields due to its significant advantages such as high energy conversion efficiency and power density.

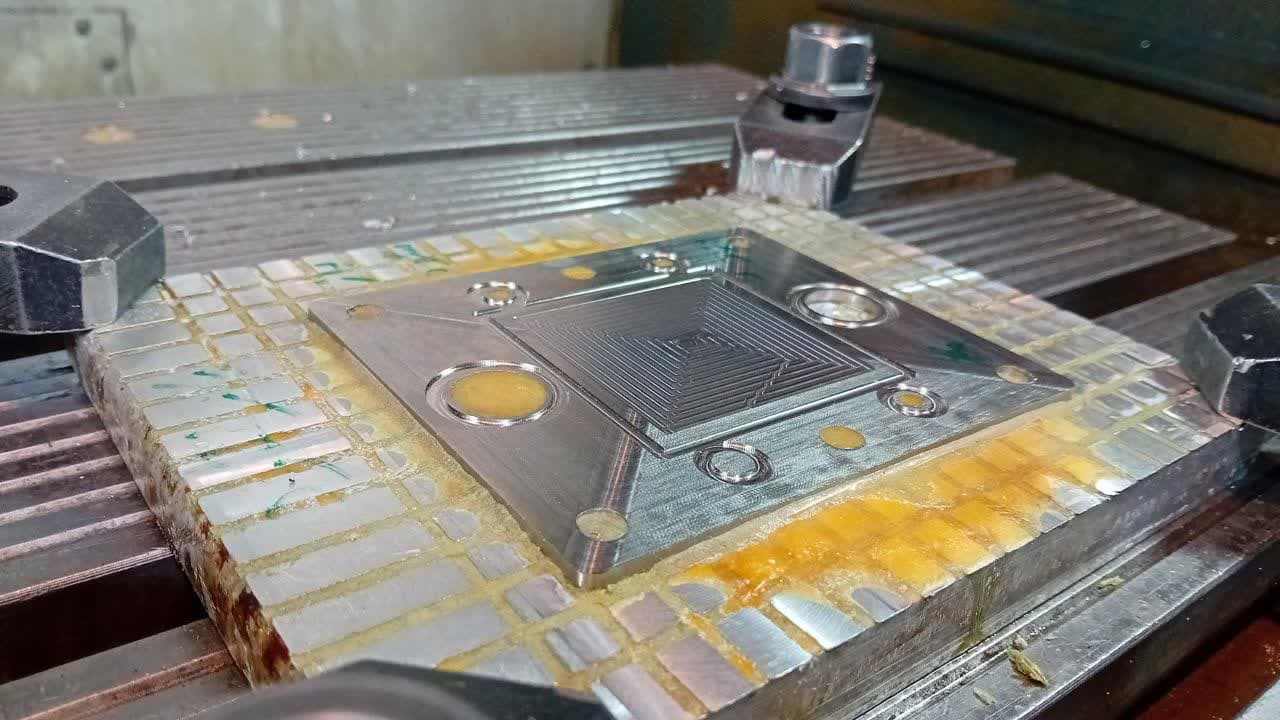

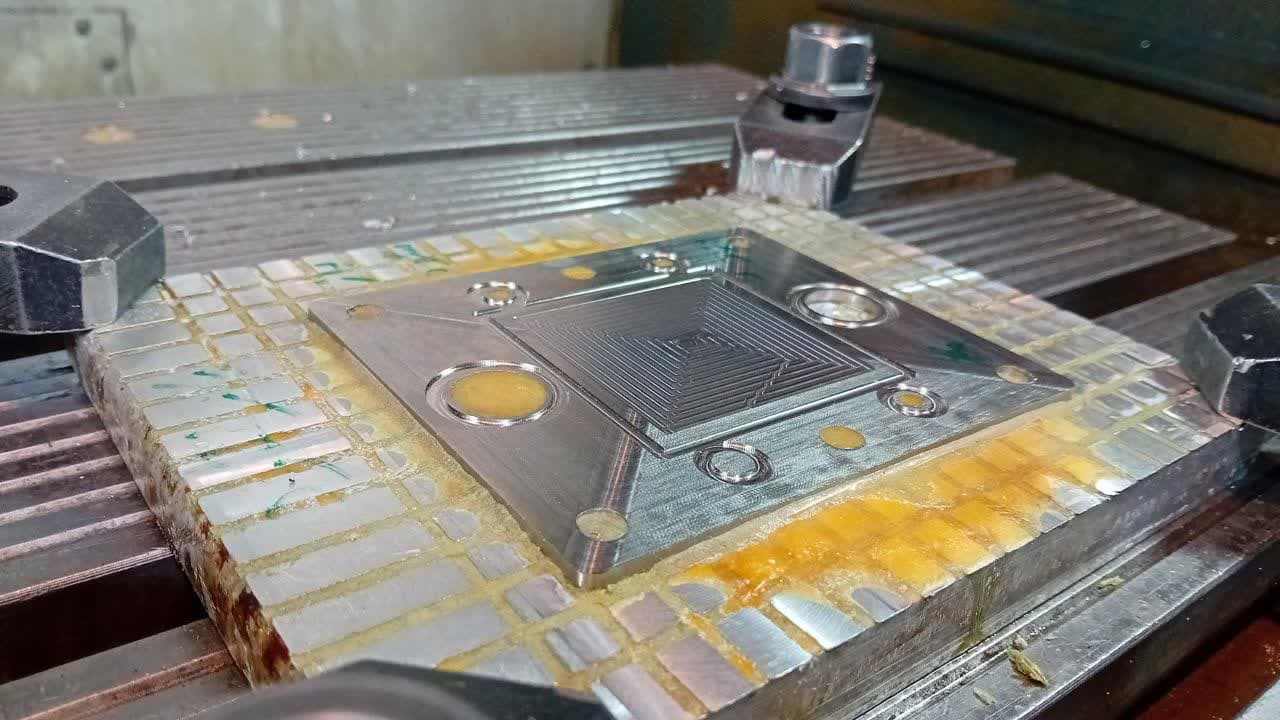

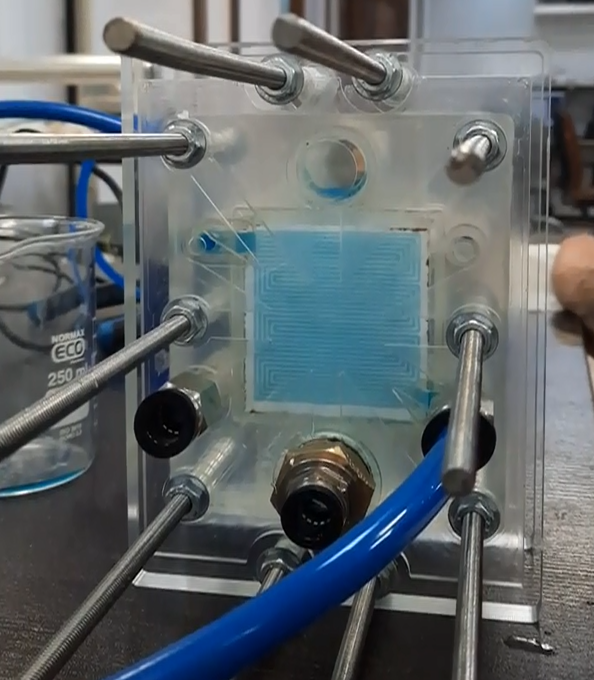

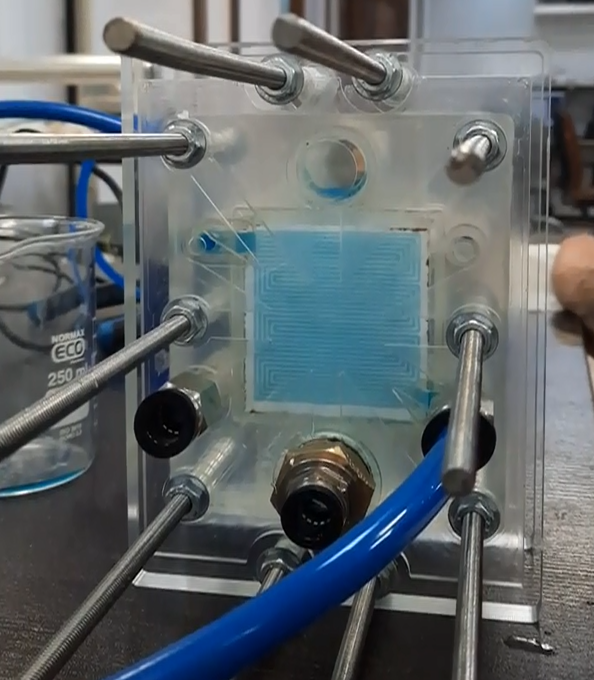

Since the beginning of 2022, Behyaar Co has commenced the production of polymer membrane fuel cells to address the fundamental needs in the energy sector. Various aspects of the project have been undertaken by the company thus far, which can be summarized as follows:

Solar energy, as a renewable energy source, is one of the most significant advantages of solar panels. Unlike other energy sources, solar energy is inexhaustible. Solar energy can be used for different purposes, which can be used to produce electricity (photovoltaic) or heat (solar thermal). Also, this energy can be used to generate electricity in areas that do not have access to the energy grid, to distill water in areas that have limited clean water resources, and to power space satellites. Solar energy can also be used in materials used in buildings, recently introduced solar energy transparent windows by Sharp.

According to this need, Behyaar Co has started building infrastructures and acquiring the necessary technical knowledge to manufacture solar panels. In this regard, one of the most important devices required for the solar panel manufacturing process, i.e., quartz stone, has been manufactured in Behyaar Co. Also, the prototype of the solar cell was also made by the same equipment.

Air pollution in big cities has many causes, one of the most prominent of these causes is fuel oil burning by industries and power plants. Diesel fuel is high in sulfur, and in combustion, in addition to sulfur oxides, it emits sulfates, nitrates, suspended particles, and other toxic gases.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Air pollution has become a major problem for people’s health in recent decades. The effects of air pollution now not only threaten people’s health, but in addition to reducing the quality of life, it also leads to an increase in health costs. Today, air pollution can be considered the biggest problem of life in big cities and even small towns, along with economic problems and traffic. Air pollution in major urban centers stems from various factors, with one of the most significant being the combustion of fuel oil by industries and power plants. Diesel fuel, containing high levels of sulfur, emits not only sulfur oxides but also sulfates, nitrates, suspended particles, and other harmful gases during combustion. Therefore, Behyaar Co. has developed a solution to mitigate air pollution by converting sulfur present in exhaust gases into high-grade sulfuric acid. This technology, validated through over 50 implementations across 25 countries, yields acid with a concentration of 98% efficiently and economically. It purifies the wet gas exiting upstream factory furnaces. Its adaptable structure and simultaneous reduction of high SO3 percentages make it applicable for treating multiple gas streams in diverse facilities, including copper mines, steel mills, and cement factories.

Iran possesses significant reserves of helium within its gas fields; however, there has been a lack of infrastructure for extracting helium from natural gas. This underscores the importance of research into the most effective methods for extracting this valuable gas. Published statistics indicate that global demand for helium is growing at a rate of 5-7% annually. In recent years, several helium recovery facilities have been installed and operationalized in Algeria, Qatar, and Australia. Currently, Qatar extracts an average of 25 million cubic meters of helium gas annually from the South Pars joint field. South Pars is presently recognized as the largest reserve of this ultra-light gas, comprising over 29% of the world’s helium reserves. Following this joint gas field between Iran and Qatar, Russia and the United States of America possess the largest helium reserves globally. However, considering these developments, it is predicted that in the near future, global demand for helium will surpass its production capacity. This imbalance in helium supply and demand is expected to drive up helium prices. Therefore, Behyaar Co has utilized the membrane process method to extract helium from natural gas. Among various polymeric and non-polymeric membranes, polymeric membranes have been selected for their flexibility, process ability, and cost-effectiveness. Since the molecular structure of polymers significantly influences gas permeability and selectivity, glass polymer has been chosen over rubber polymers for this project. The arrangement of atom components in the polymer matrix and the resulting polymer strength inhibit polymer part rotation, resulting in a rigid and robust polymer. Currently, a semi-industrial setup for this method has been established.

To register questions and get more information, contact us through the form below.