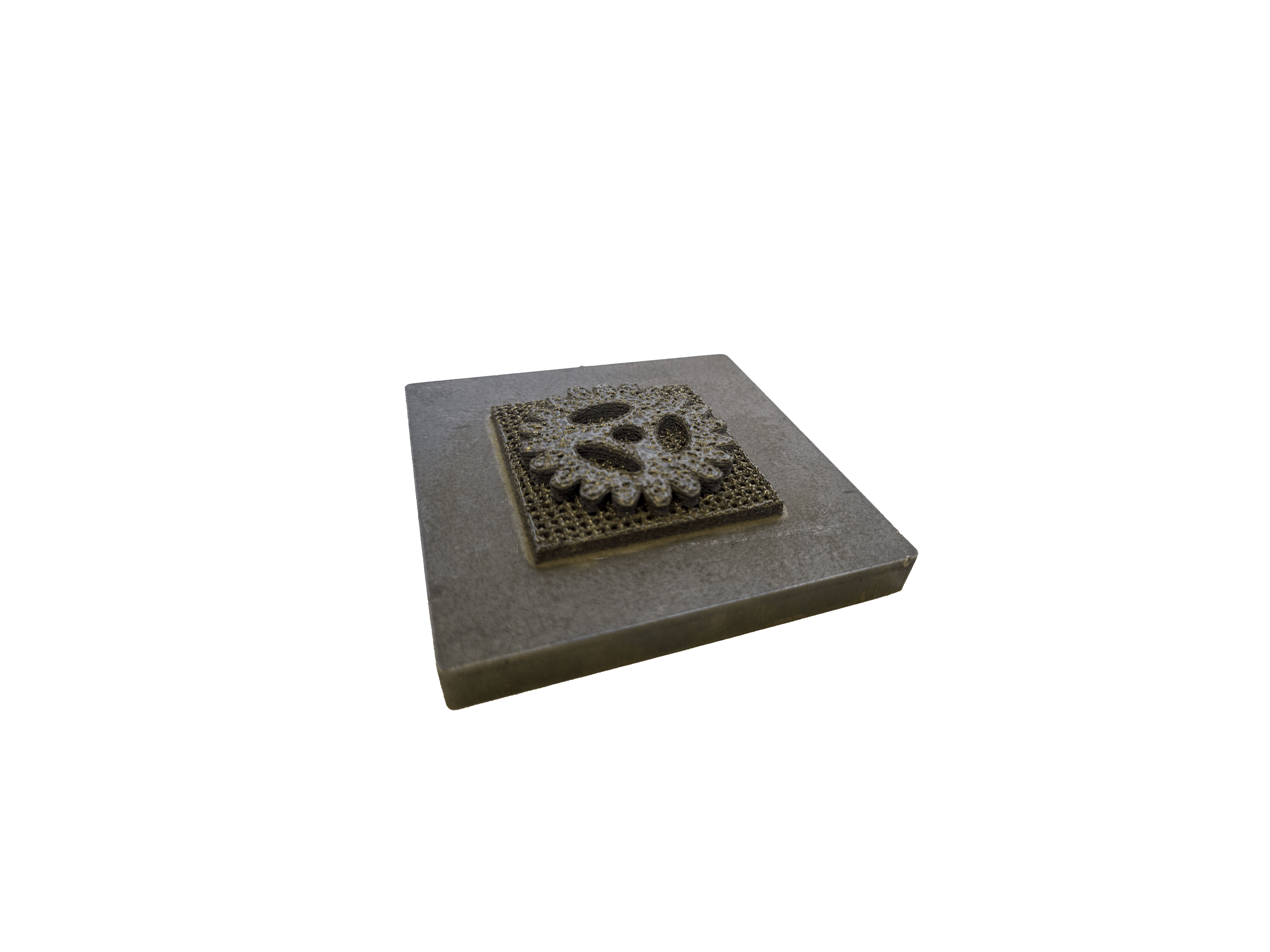

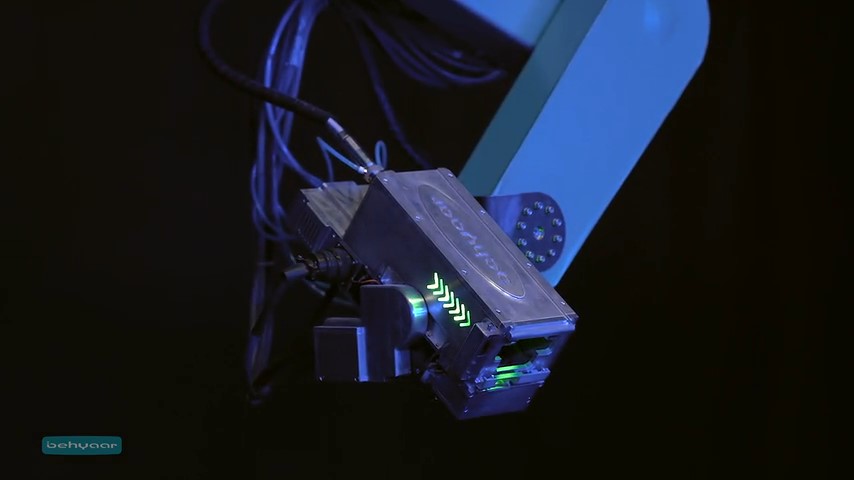

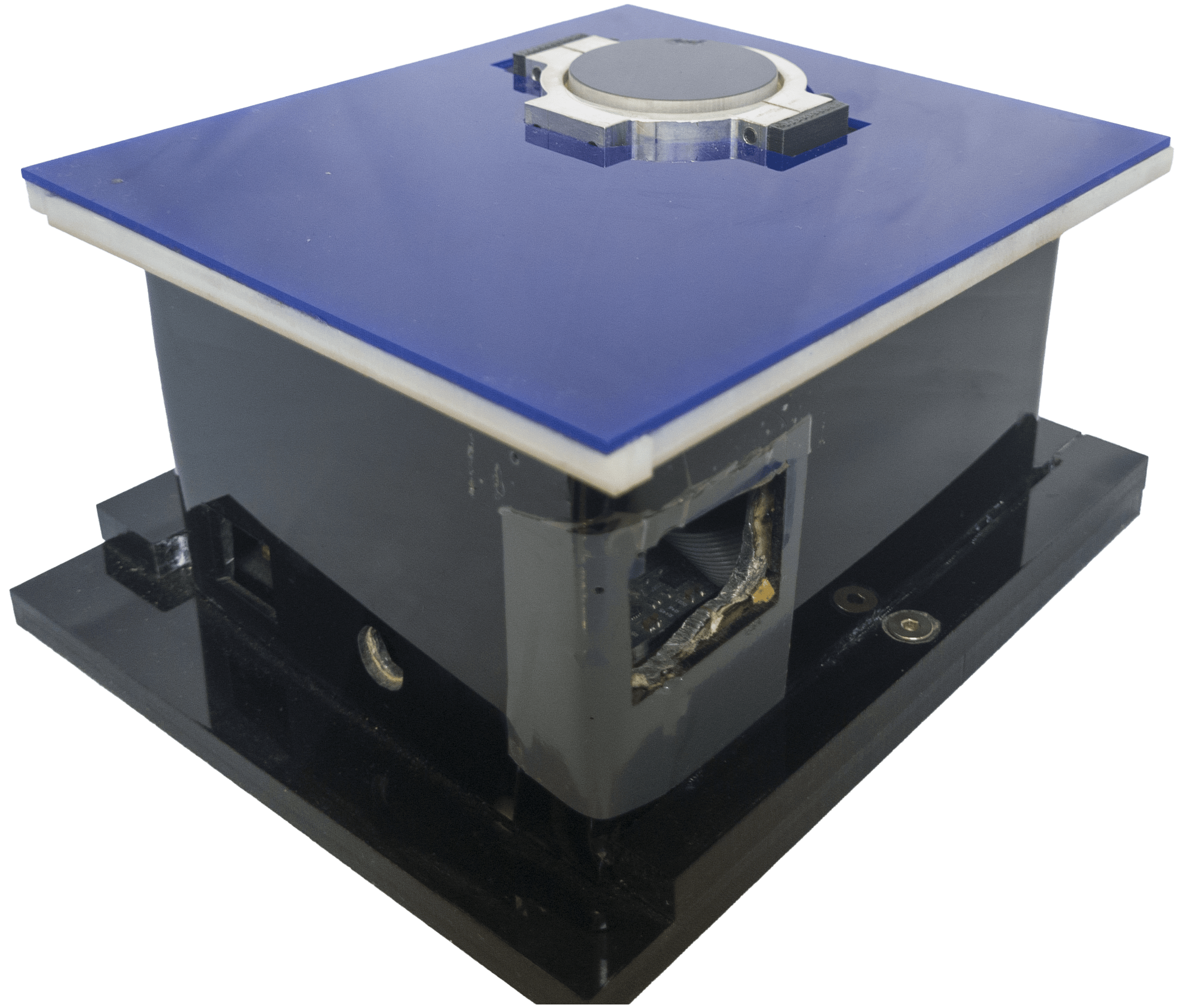

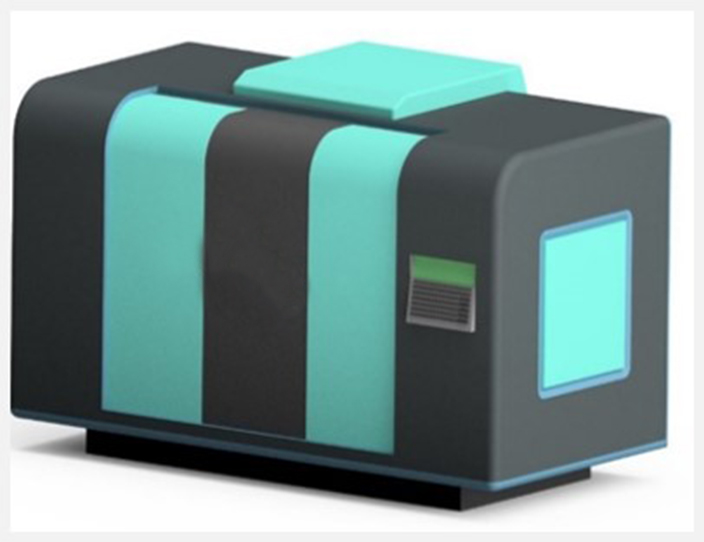

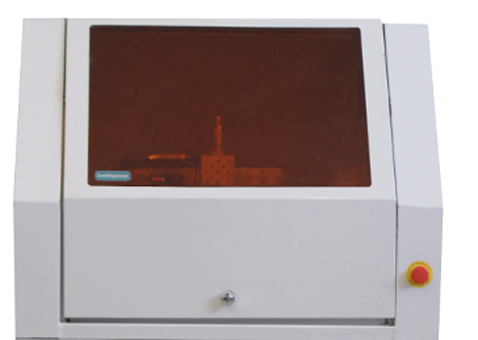

Behyaar Co’s printer stands as the most advanced device for printing parts with intricate geometric complexity, thin walls, channels, internal cavities, and small dimensions. It employs cutting-edge SLM (Selective Laser Melting) techniques, catering to specialized applications, especially in industries requiring lightweight parts with optimized designs. This printer excels in directly creating precise part geometries without the need for machining, thus reducing material waste, particularly for expensive metals.

Key features of this product include:

– Custom-designed powder charging mechanism to minimize powder consumption.

– Utilization of a 500-watt fiber laser.

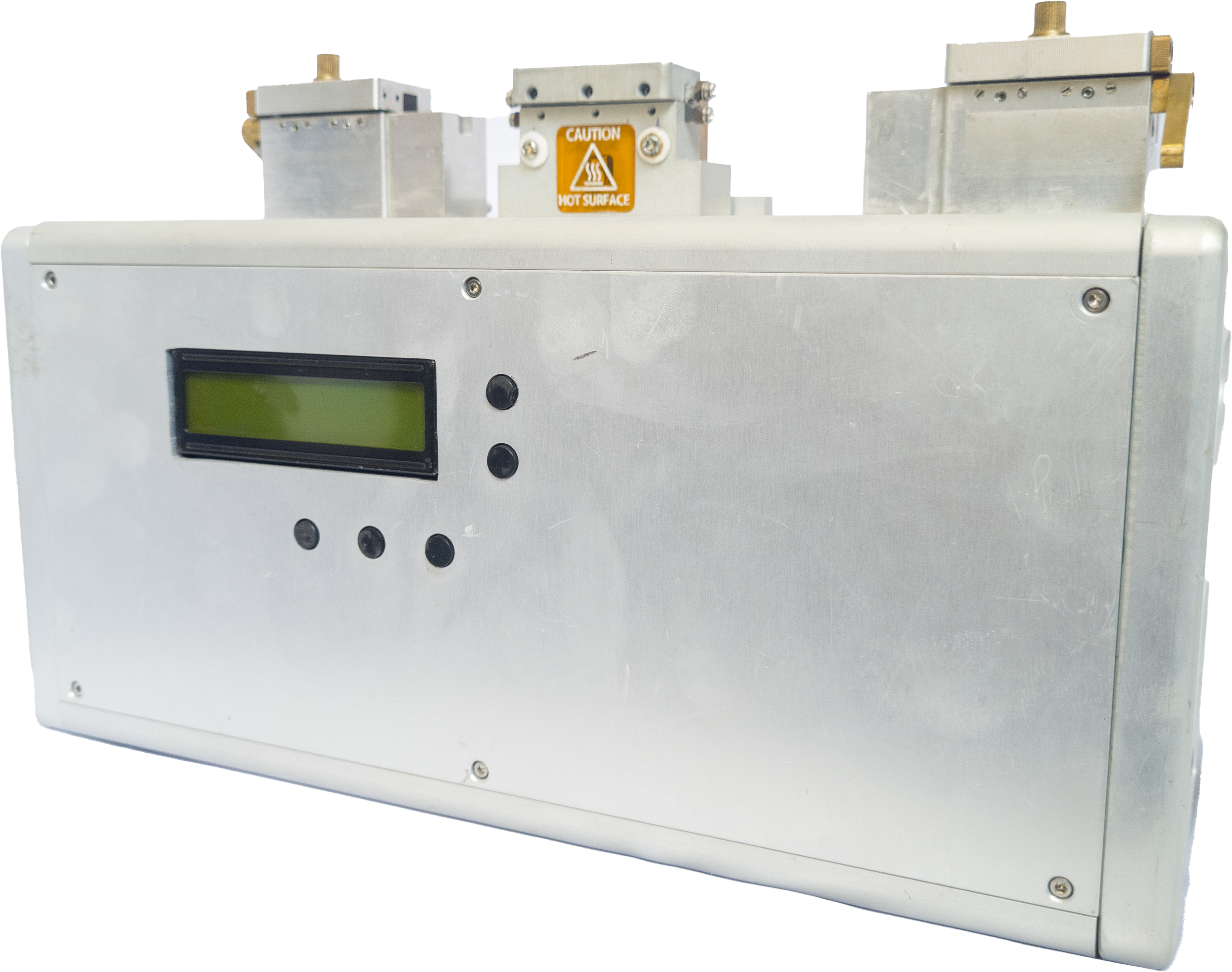

– Advanced preheating system capable of handling parts up to 400 degrees Celsius.

– High printing speed.

– Customization for printing superalloy and heavy metals such as titanium, Inconel, and tungsten.

– Automatic argon gas circulation and purification system.

– Advanced powder sieving system.

– Integration with specialized 3D printing software.