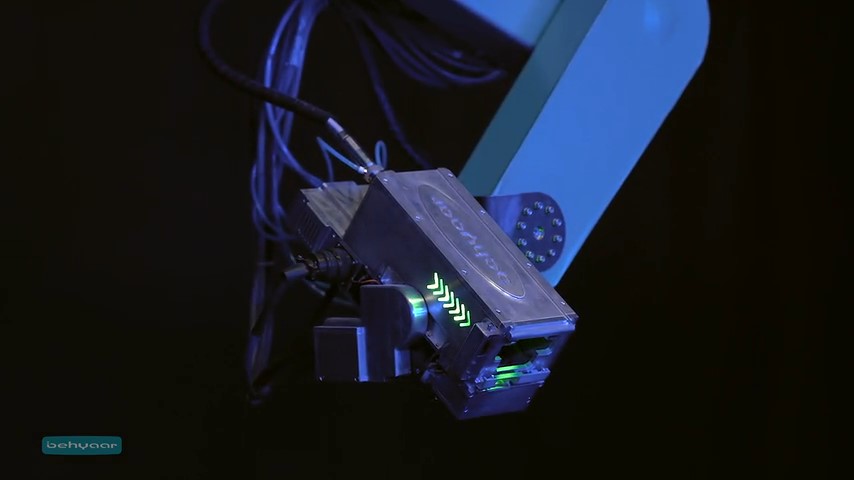

The optical fiber fusion splicer by Behyaar Co is optimized for connecting two large core optical fibers, ensuring precise connections. Its advantages include:

– Wide thermal dynamic range for fusing optical fibers with coating diameters from 80 micrometers to 1 millimeter.

– Utilization of a high-resolution optical system (200X) for core alignment.

– Integration of state-of-the-art technology to minimize fusion losses.

– Provision of strong and stable fusion connections.

– High-temperature tolerance and portability.

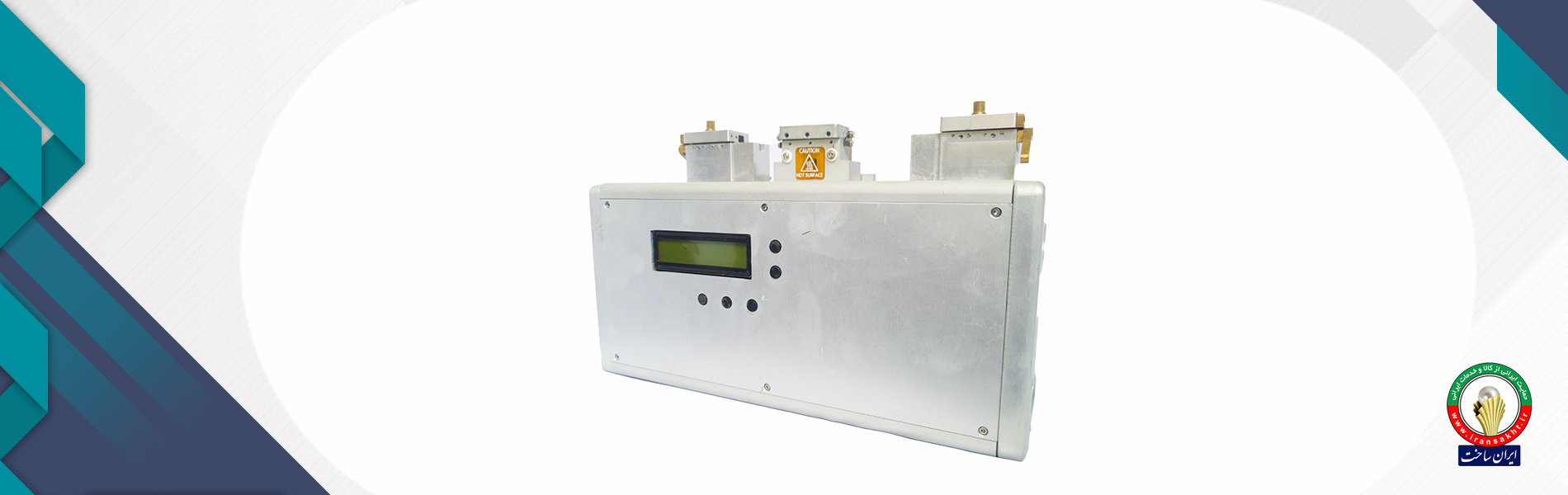

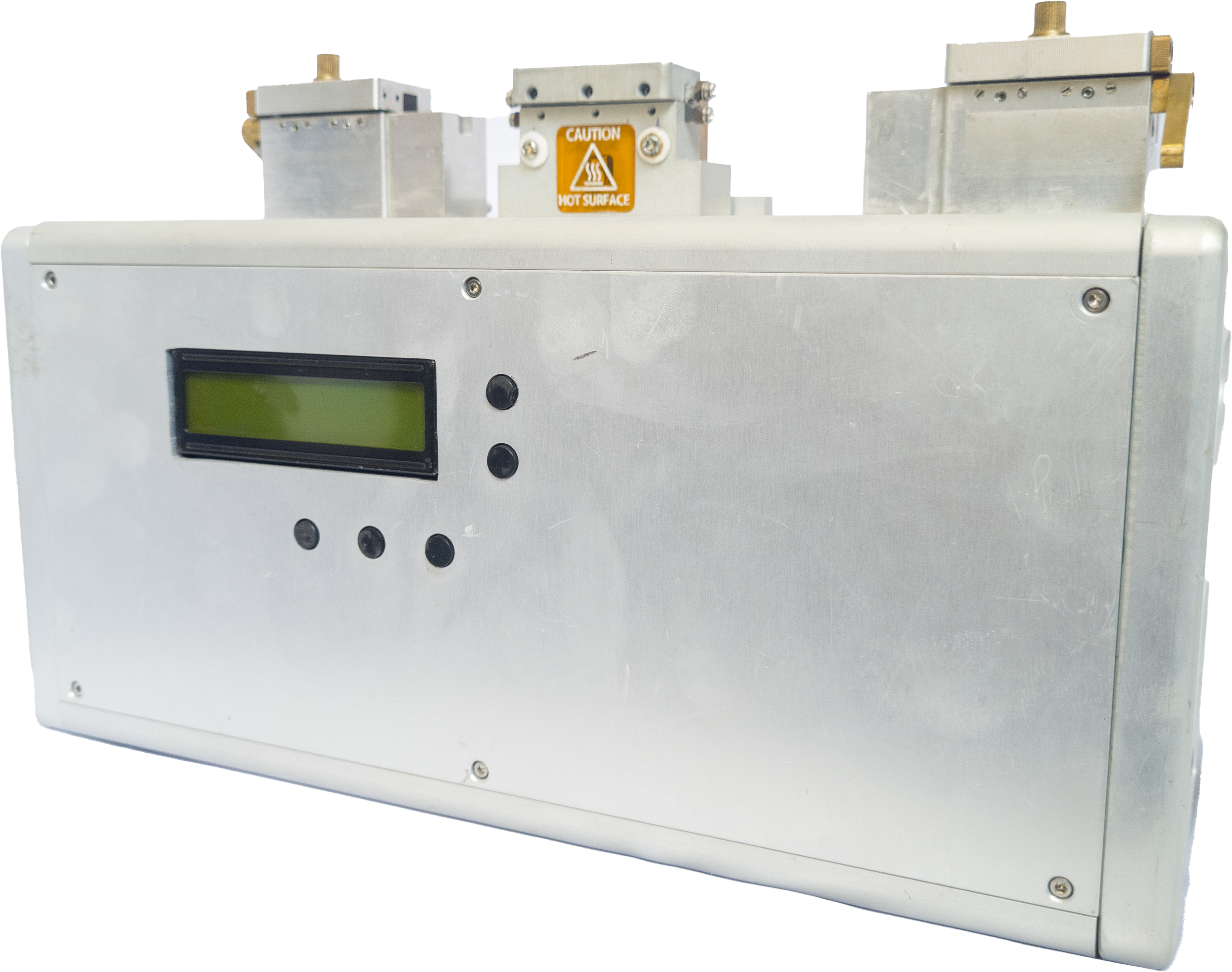

Stripping, a process of removing protective polymer coatings around optical fibers, precedes fusion splicing. The stripping device’s advantages and capabilities include:

– Acceptance of fibers with coating diameters from 100 to 1360 micrometers.

– Full programmability for fiber diameter and length.

– High strength and precise stripping of various optical fibers.

– Thermal separation mechanism for fiber protection.

– User-friendly operation with a detachable fiber holder.

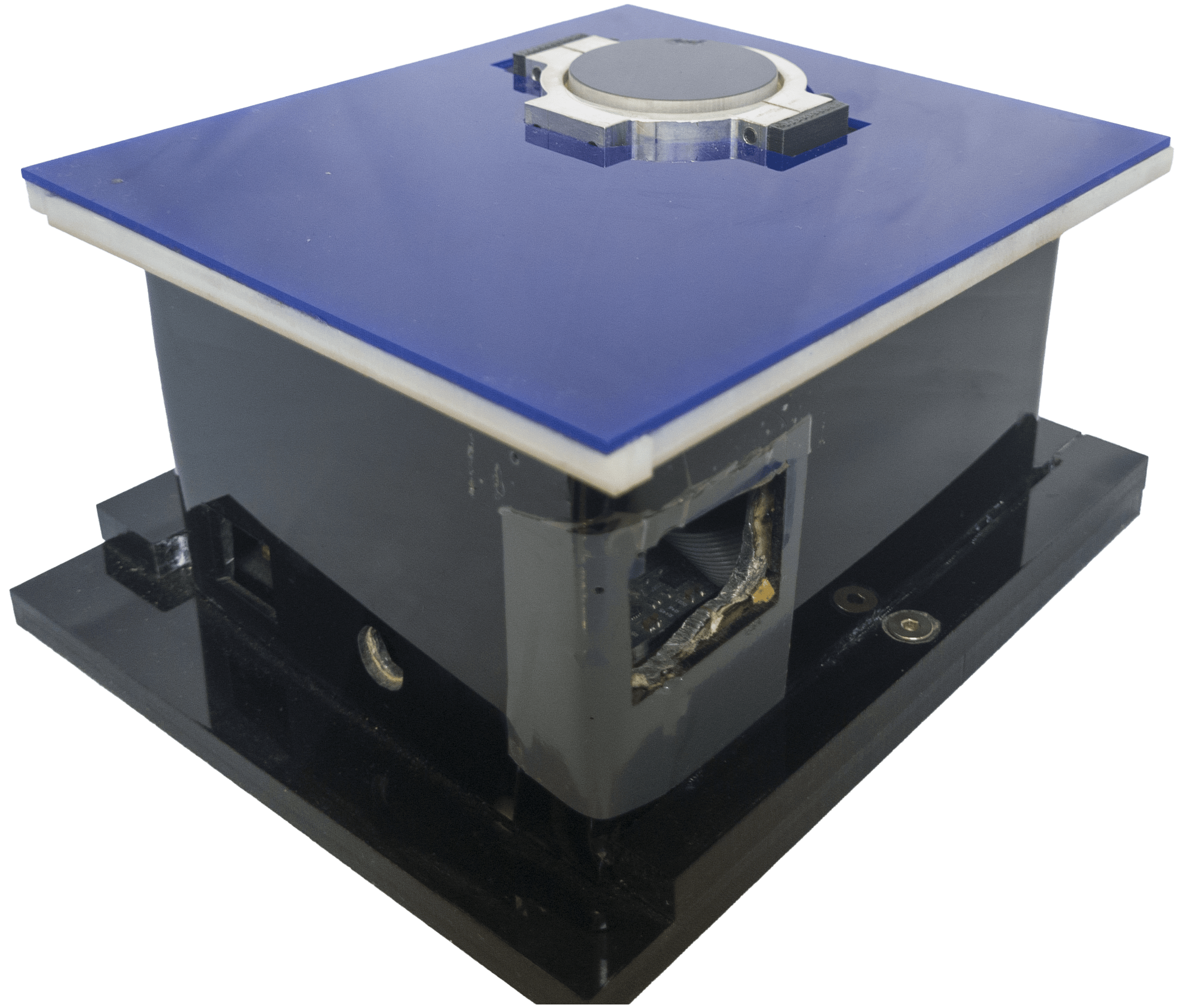

A fiber cleaver ensures a controlled process for cutting fibers smoothly for connection or fusion. Its advantages include:

– Capability to cleave large core fibers with coating diameters from 80 micrometers to 1 millimeter.

– Ability to cleave single-mode and multi-mode fibers precisely.

– Intelligent user interface for adjusting cleaving parameters.

– Cleave tolerance of ±0.5° for smooth cleaves.

– Operation at 12.5 VDC, 5 A.