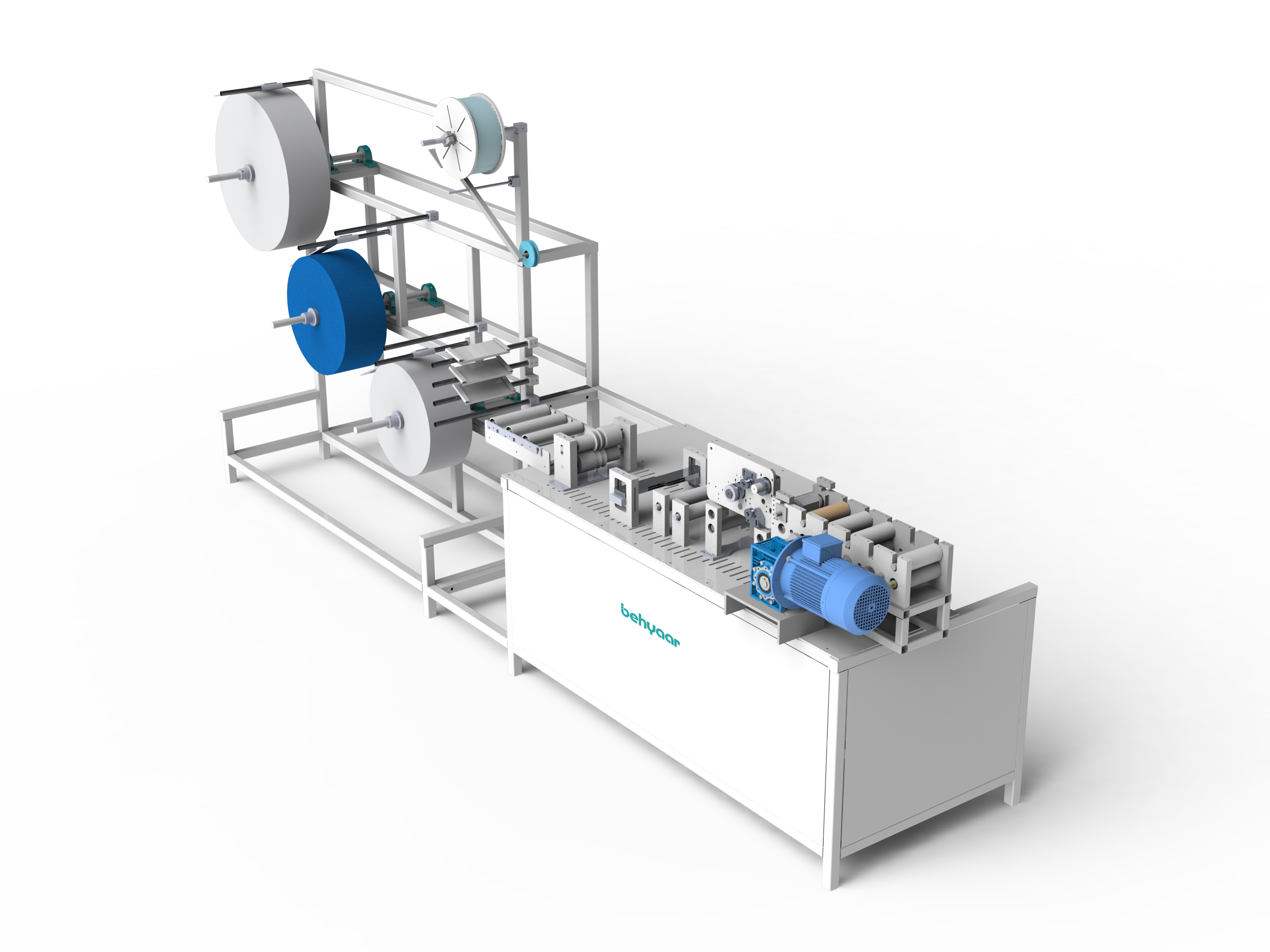

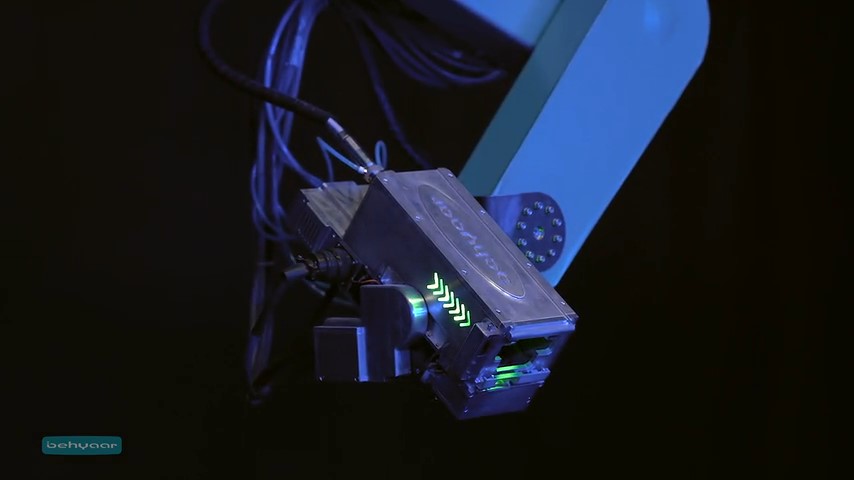

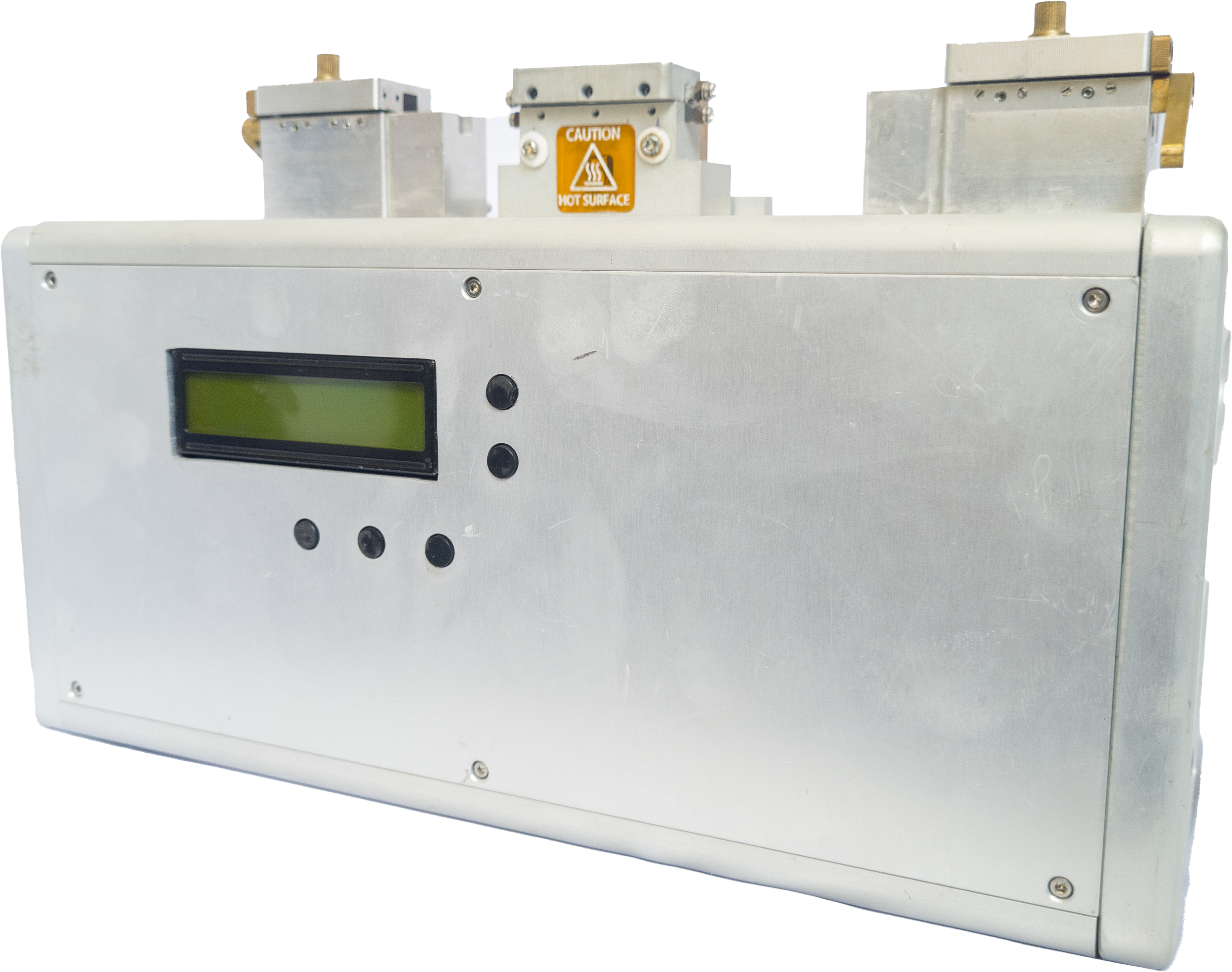

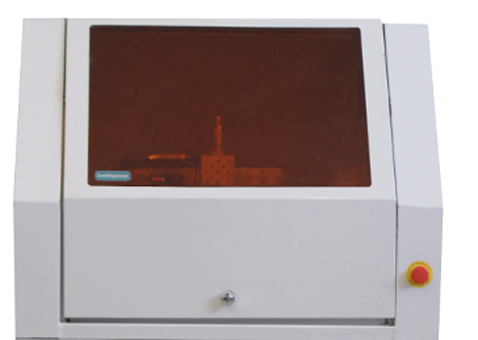

The three-layer mask, also known as a surgical mask, is one of the most common types of masks used to prevent the spread of respiratory diseases. The developed machine enables automatic production of medical three-layer masks with ultrasonic stitching. Additionally, the company has acquired the capability to produce N95 mask machines, which are designed to prevent at least 95% of airborne particles from entering the body. The features of the “Bahyaar Co” mask manufacturing machine are:

– Production of four-layer and five-layer masks

– Production speed of the mask body before front stitching: minimum of 12 pieces per minute

– Voltage: 220 volts

– Power: 8 kW

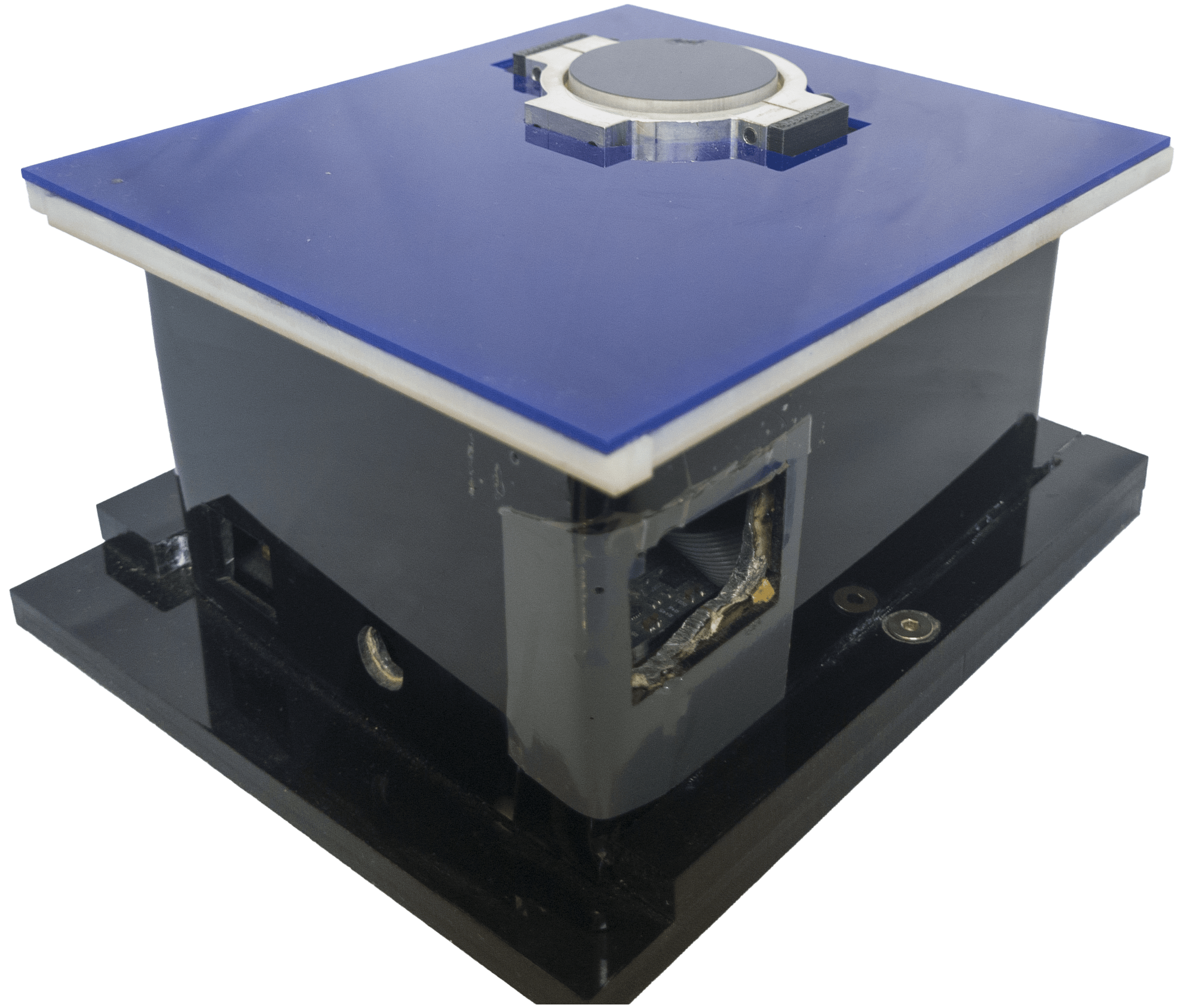

– Stitching system: Ultrasonic

– Machine dimensions: 510 x 100 x 210 cm

– Minimum required fabric width: 14.5 cm

– Front part of the mask stitching method: Using a separate ultrasonic machine

– Hidden memory installation method: Manual